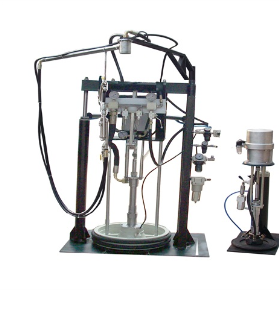

打膠機點膠不良的六大核心因素!

點膠的效果對產品質量是有很大影響,所以很多客戶都十分關注打膠機點膠不良的情況,但目前出現點膠不良的情況更多是操作原因導致,下面品耀將導致打膠機點膠不良的六大核心因素給大家分享:

The effect of dispensing has a great impact on the quality of products, so many customers are very concerned about the poor dispensing situation of the glue dispensing machine, but at present the poor dispensing situation is more caused by operational reasons. The following six core factors will lead to poor dispensing of the glue dispensing machine to share with you:

點膠機針頭的選擇:打膠機針頭的不合適亦會導致出膠過多或過少的現象,所以建議針頭的直徑盡量控制在點膠量直徑的一半左右,這樣可以保證更大化的提升生產效率;

Needle selection of dispensing machine: The inappropriate needle of dispensing machine will also lead to excessive or too little glue, so it is suggested that the diameter of needle should be controlled as far as possible at about half the diameter of dispensing volume, so as to ensure greater production efficiency;

點膠壓力的控制:使用打膠機進行點膠的時候要控制好壓力,具體需要根據點膠的需求、膠水的特性、溫度、環境情況進行有效調節,壓力過大容易造成膠量過多,過小又容易引起膠量過少等影響效果的情況!

Control of dispensing pressure: When dispensing with glue dispensing machine, pressure should be well controlled. It needs to be adjusted effectively according to the demand of dispensing, the characteristics of glue, temperature and environment. Excessive pressure can easily lead to excessive glue content, too small and too little glue content.

除了打膠機設備的操作因素外,膠水自身亦是很重要的影響因素:

In addition to the operating factors of glue beater equipment, glue itself is also an important factor:

膠水粘度: 膠水的粘度越高,所出膠點就會變小,甚會出現拉絲的現象。而粘度過低的話則會讓點出的膠點擴大,若沒把握好容易出現浸染焊盤,所以膠水黏度方面的因素一定要控制調整好!

Glue Viscosity: The higher the viscosity of glue, the smaller the adhesive point will be, and even the phenomenon of wire drawing will occur. If the viscosity is too low, the point will be enlarged. If you do not grasp it well, it is easy to appear the dipping pad. Therefore, the factors of glue viscosity must be controlled and adjusted well.

膠水溫度:由于不同膠水的性質不一樣,其需要儲存的溫度亦都并不一樣,若是儲存環境不合適容易導致膠水變質,影響出膠效果和膠水的性質,而且除了合理存儲外,以讓膠水與周圍溫度更好的適應!

Glue temperature: Because of the different nature of different glue, the temperature needed to store is also different. If the storage environment is not suitable, it will easily lead to deterioration of glue, affecting the glue effect and the nature of glue. Besides reasonable storage, in order to make the glue better adapt to the surrounding temperature! uuuuuuuu

膠水不能有空氣介入:如果膠水進入了空氣,則在點膠過程容易會出現打空的現象,這樣亦都會導致點膠不良的情況,所以這是必須要注意的!

Glue can not have air intervention: if the glue into the air, in the process of dispensing will easily appear empty phenomenon, which will also lead to poor dispensing, so this must be noted!

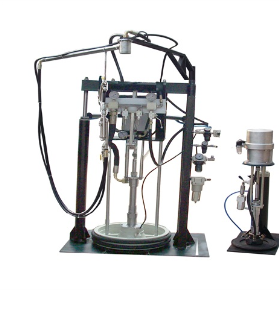

目前出現打膠不良的情況與打膠機設備自身質量問題不大,更多是因為操作的不合理導致。

At present, the bad situation of gluing and the quality problems of gluing machine equipment are not big, more because of the unreasonable operation.

上一篇:怎么處理自動點膠機焊接不良的問題?

下一篇:點膠機在點膠時要注意什么?